Onion Peeling Machine

New type onion peeling machine WOP-15T

World's most effective onion peeling system

World's largest onion peeling production quantity as single machine

Over 95% Peeling Rate Guaranteed

| Model | WOP-15T (Large capacity peeler) |

|---|---|

| Specification | 1200W X 2800D X 1700H |

| Peeling Method | Air injection (Peeling with the air pressure) |

| Output | 1h/1900~2200kg, Day(8h)/15~17. 6ton (15tons average) |

| Peeling rate | Over 95% |

| Power Consumed | Three phase 380V 2.0kw |

| Required compressor quantity | Over 75hp |

Automatic cleaning function of washing part

Over 95% Peeling Rate (By controlling the function of the peeler optimally, it is possible to keep the peel rate at least 95% regardless of the size and shape of the onion and the state of the raw material)

Automatic cleaning function of washing part (You have the option of automatically washing the device though the brush that removes onion's dust and dirt on the roller that is to be peeled, and it can increase the hygiene during production and reduce the time and labor costs required for cleaning.)

Peeling rate : Over 95%

New type onion peeling machine WOP-10T

World's most effective onion peeling system

Over 95% Peeling Rate Guaranteed

| Model | WOP-10T |

|---|---|

| Specification | 1050W X 2500D X 1500H |

| Peeling Method | Air injection (Peeling with the air pressure) |

| Output | 1h/1200~1400kg, Day(8h)/9~11ton, ±10tons average) |

| Peeling rate | Over 95% |

| Power Consumed | Three phase 380V 1.5kw |

| Required compressor quantity | Over 50hp (Two 20 horsepower pistons can be used) |

| Output | Depending on the condition and size of the material, the production may increase or decrease in more than 70 ¢ standard. |

| Peeling rate | You can maintain over 95% peeling rate regardless the size of onion and condition of raw material. |

Peeling rate : Over 95%

New type onion peeling machine WOP-5T

World's most effective onion peeling system

Over 95% Peeling Rate Guaranteed

| Model | WOP-5T |

|---|---|

| Specification | 900W X 2000D X 1200H |

| Peeling Method | Air injection (Peeling with the air pressure) |

| Output | 1h/600~800kg, Day(8h)/4.8~6.4ton, ±5tons average |

| Peeling rate | Over 95% |

| Power Consumed | Three phase 380V 1.5kw |

| Required compressor quantity | Over 30hp (Two 20 horsepower pistons can be used) |

| Output | Depending on the condition and size of the material, the production may increase or decrease in more than 70 ¢ standard, |

| Peeling rate | You can maintain over 95% peeling rate regardless the size of onion and condition of raw material. |

Peeling rate : Over 95%

Small capacity onion peeling machine order production (Day1-4ton)

Over 95% Peeling Rate Guaranteed

der producing the size and amount of onion peeler according to the daily production quantity that consumer requires, we will build production equipment to produce optimal onion production by minimizing the budget and production space for production equipment.

Peeling rate : Over 95%

Onion Root / Stalk Automatic Cutting Machine WOC-5T

when producing 5 tons, 3-4 people of manpower saving effect

| Model | WOC-5T |

|---|---|

| Specification | 700W X 2700D X 1800H |

| Output | 1h/700~800kg, Day(8h)/5.6~6.4ton (required person, 1 person) |

| Power Consumed | Three phase 380V 1.5kw |

Output

Depending on the condition and size of the material, the production may increase or decrease in more than 90 ¢ standard, the cutting thickness of root and stalk can be freely adjusted and depending on proficiency, you can control the inserting speed.

Output

- 1min/80~100EA Cutting

- 1h/4800~6000EA Cutting

- 4800EA X 150g = 720kg/H

- 720kg X 8h = 5760kg/Day

People required when producing onion root/ stalk cutting 5ton

- 5~6 people required when doing hand work.

- 1~2 people required when using the cutter

when producing 5 tons, 3-4 people of manpower saving effect

Win Tech Co., Ltd. will build the most effective, and best peeled onion producing system.

1. Efficiency of peeling off the onion peeler

Win Tech Co., Ltd. onion peeler guarantees over 95% peeling rate. Traditional peeling technologies only have a short performance at the initial stage of introduction, but the lifting rate is significantly lowered over time and the durability of the equipment is weak. Win Tech Co., Ltd. onion peeling technology has increased the peeling performance and durability to maintain over 95% peeling rate, and is designed for the consumer to easily replace the consumables.

2. Automation

By Automating all processes such as removal of raw material from inserting the raw material -> root and stalk cutting -> washing -> drying -> screening -> packing -> by-product transfer collection, we can build onion production line to reduce labor costs and increase productivity.

3. Hygiene

We will build for the worker to be completely separated from the noise and dust, and it is constructed so that the peeled onion can be produced in a pleasant space by compartmenting the chamber of the raw onion input and peeler chamber, and installing the dust collecting facility.

based on building peeled onion producing equipment in many companies such as Hyundai Green Food, Lotte Food, Nonghyup, Farming Corporation, Agricultural Company Coperation, we promise to build Korea's best peeled onion producing system.

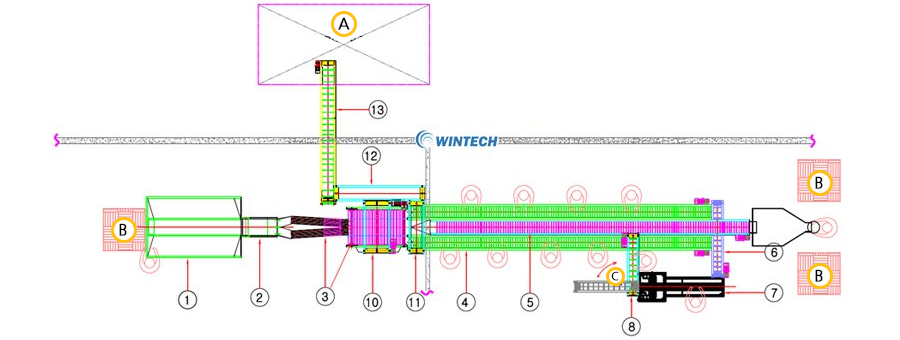

Peeled onion production equipment layout drawing

Peeled onion per day / 15 tons Production line Lay Out

| NO | DESCRIPTION | SIZE | MATERIAL | QTY |

| 1 | Input Hopper Conveyor | 1600 x 2500 | SUS304 | 1 |

| 2 | Input elevator Conveyor | 400 X 1600 | SUS304 | 1 |

| 3 | Onion Peeler -15 ton | 1000 X 3200 | SUS304 | 1 |

| 4 | Screening Conveyor | 400 X 8000 | SUS304 | 2 |

| 5 | Completed Product Transport Conveyor | 400 X 8000 | SUS304 | 1 |

| 6 | Lift Transport Conveyor | 400 X 2000 | SUS304 | 1 |

| 7 | Onion Cutter | 500 X 2240 | SUS304 | 1 |

| 8 | Completed Product Elevator Conveyor | 400 X 1500 | SUS304 | 1 |

| 9 | By-product Transport Conveyor 1 | 400 X 8000 | SUS304 | 1 |

| 10 | By-product Transport Conveyor 2 | 400 X 2000 | SUS304 | 1 |

| 11 | By-product Transport Conveyor 3 | 600 X 2000 | SUS304 | 1 |

| 12 | By-product Transport Conveyor 4 | 400 X 3500 | SUS304 | 1 |

| 13 | By-product Elevator Conveyor | 400 X 4500 | SUS304 | 1 |

| 14 | Electric control box (control box) | 2 | ||

| A | Amol Tanks / By-product Collecting | |||

| B | Moving | |||

| C | Pallets |

Key points for Win Tech Co., Ltd. peeled onion production equipment technology

When the raw material is input, the hopper is manufactured so that the net, the box, and the tone bag can be input, and the input of the raw material up to the peeling machine is smoothly and automatically inputted. Peeler is a technology that can maintain a rate of 95% or more even if any raw material is input, the amount of peeling is the world's largest production volume for a single machine, and it has the ability to peel more than 15 tons per day. Onion roots and stalks can be configured to be cut manually or semi-automatically, and all the byproducts generated from the onion removal line are automatically discharged to the outside by the transport conveyor.

Peeled onion production equipment installation example photograph

Peeled onion production equipment installation work

Features : By constructing the Inserting / Peeling room and screening / packaging room with partition blocking the noise, dust and odor, it makes fresh working lines for screening line, sorting line and packaging line.

Partition construction

- A : Peeling chamber

- B : Screening/ washing / packing room

Work area separated by partitions

- A : Inserting chamber / Peeling chamber

- B : Screening/ washing / packing room

Three-stage Conveyor Onion Root / Stalk Removal and Completed Product Air Shower Part

The onion which has been firstly peeled by the peeler is conveyed on both conveyors, and the peeled onion completed product is transported separately to increase/decrease the speed according to the production amount so as not to become stagnant and contaminated.

1 : #60 chain ball rotation type

2 : 6¢ round bar

3 : Thickness : 25mm

Semi-permanent use available

Peeled Onion Sorting / Packaging Equipment

Air washing, water pressure washing possible

Screening Conveyor

It is manufacture for the sludge to not attach to the chain, and as the sludge is collected and transported to the lower sludge conveyor by the chute, it is efficient screening conveyor with zero failure rate to create a clean production workshop.

Onion roots / stalks automatic cutter delivery installation case

Lotte Food, Onion roots / stalks automatic cutter delivery and installation

Onion inserting scene that inserts to the onion roots/ stalks automatic cutter

Features: When cutting the 5 tons of onion roots, stalk 5 ~ 6 people were required, but after introducing the automated cutter, 5 ton is processes with 2 people, giving reduction effect in 3~ 4 people manpower, reduction of labor costs by at least KRW 5 million per month

More precise cutting is possible if the operator is skilled

Equipment for washing and slicing cut onions as onion roots/ stalks automatic cutter

Production of Sliced Onions for Lotteria Hamburgers

Delivery installation case of onion roots / stalks automatic cutter

Hyundai Green Food, onion roots / stalks automatic cutter delivery installation

Onion hopper transport conveyor and automatic input elevator conveyor

Onion hopper transport conveyor / automatic input elevator conveyor

We will order, production so that the inserting the onion raw material (ton bag, net, box) could be easy. It is possible to reduce labor costs and increase productivity, by automation of onion raw material input.

Transport and collecting the onion skin (by-products) that are generated when the producing peeled onions

Transport and collecting the onion skin (by-products) that are generated from onion peeler and screening line

- Sludge gathering Tone bag

- Sludge collecting Amroll tank

Hand work onion peel workstand

By using the air gun, it is manufactured for you to manually remove the onion, when peeling, the by-products fall into the bag, the dust is sucked up to the outside and discharged to the outside, making it possible to produce onion in a pleasant space.

The most efficient Win Tech Co., Ltd. peeled onion production equipment system in the world

Point : There are many cases where the conventional technology has a tendency for the person to fall off again with the air gun due to the low removal rate even when the removing machine is introduced. Win Tech Co., Ltd. onion peeler, boasts a peeling rate that is close to 100%, and you do not have to take the airgun again and you can save on labor costs.

Peeling rate : Over 95%