Potato Peeler

New style potato peeler WPP-02

Win Tech Co., Ltd. New style potato peeler of "World's best performance"

Having applied for international patent(PCT) (Product that has been applied for patent in more then 30 countries of potato's main consumer country)

| Model | WPP-02 |

|---|---|

| Specification | 900W X 900D X 1400H |

| Output | 1h/150~200kg, Day(8h)/1200~1600kg |

| Weight | 150kg |

| Power Consumed | phase 380V 1.5kw |

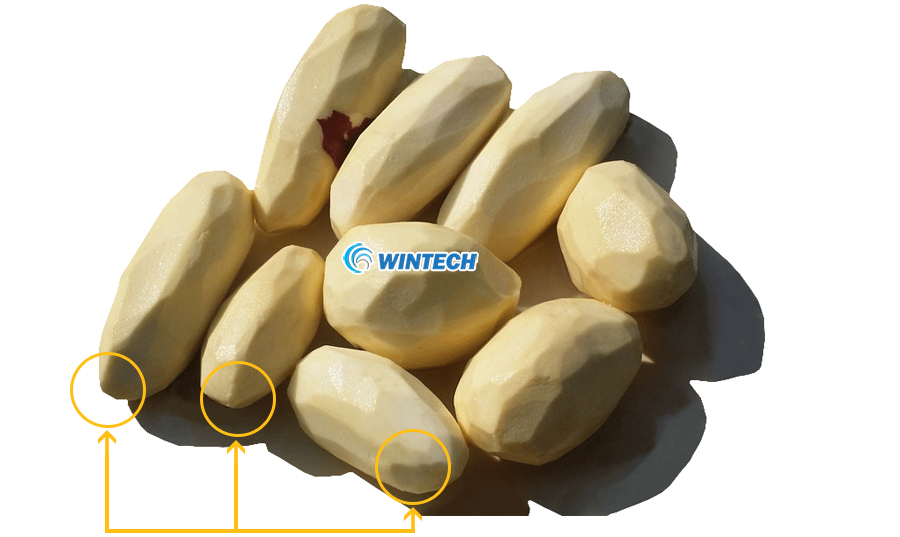

Loss rate minimization without bruise, scar and scratch... more elaborately... more prettier than peeled by a person...

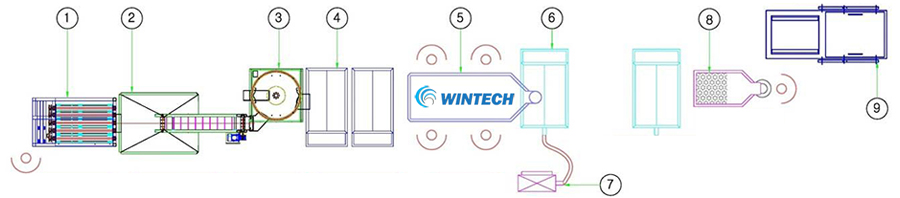

Continuous Conveyer-type Potato Peeler WPP-01

Patented products / Conveyor type continuous potato peeling

1: Inlet / 2 : peel section / 3 : outlet

| Model | WPP-01 |

|---|---|

| Specification | 1100W X 3200D X 1500H |

| Output | 1h/400~500kg, Day(8h)/3200~4000kg |

| Weight | 800kg |

| Power Consumed | phase 380V/3.0kw |

New technology of Win Tech Co., Ltd , The merits of potato peeler

- Latest blade cutting technology with the lowest loss rate among all existing technology, peels elaborately, and minimizes bruises and damages

- Uses no water excluding occasional injection of water by thin injection nozzle during bulb peeling

- Peels elaborately and equally along the shape of the potato, leaving only the eyes to be removed

- Thickness of peel (skin) adjustable by adjusting the height of the peeling blade according to the characteristics of the potato

- Surface of the potato is peeled smoothly and spotlessly as if done by a human with a potato knife

- Best technology for producing school lunch peeled potatoes, as it minimizes bruises and damages even on large potatoes over 200G

- The maintenance costs can be saved by minimizing the potato peeler's maintenance costs(consumables), and it is produced for the consumer to change the consumables easily.

- Potato, sweet potato, ginger, taro, various bulbs and tubers can be effectively peeled elaborately by the blade of a knife.

Potato peel technology of Win Tech Co., Ltd. is one of the best technologies in the world for technology that cuts with the blade of a knife.

Potato peel technology with the knife blade method that enables most elaborate peeling in the world.

Sweet Potato Peeling Test

Win Tech Co., Ltd. sweet potato peel technology with the knife blade method that enables most elaborate peeling in the world.

Feature: Long sweet potatoes are cleanly peeled off by the edge of the blade.

Other Peeling Test

Tumeric (Curry material) Peeling Test

Taro Peeling Test

Ginger Peeling Test

Potato peeling related data

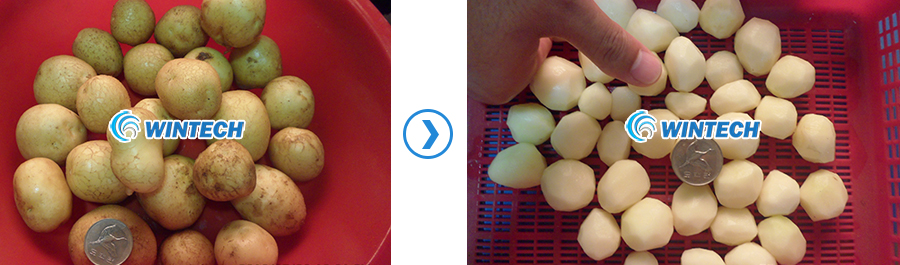

Potato that has been peeled in the size(for school lunch) of 150~200g

Feature : Loss rate

As the "world's best" conveyor type continuos potato peeler, it elaborately peels without bruise and wounds

Quantity: Within 30g ~ 40g

- Potatoes smaller than coins are also elaborately peeled.

- It is peeled in the shpae of raw potato, minimizing the loss rate, as more than 90% of potato, in case of small potato, is peeled as if it does not need any finishing, the labor costs can be reduced innovatively.

- As it is peeled elaborately by the blade, the marketability is excellent as if the peeled potato that has been produced by hand work.

Peeled potatoes of about 50 ~ 80g in size

- Features : loss rate (30~35%) / Peeling rate (99%)

- Features : Smaller potatoes than coins can be elaborately peeled

Potato peeling test

- Inserting the raw material : 3.0kg

- Peeled potato : 2.0kg

- Yield rate : 66.6%

- loss rate : 33.4%

- Peeling rate : 99%

Single item set device of popato peeler

1 : popato peeler / 2 : Screening work stand / 3 : Potato storage water tank

1 : Potato washer / 2 : Potato automatic inserting conveyor

Delivery installation case

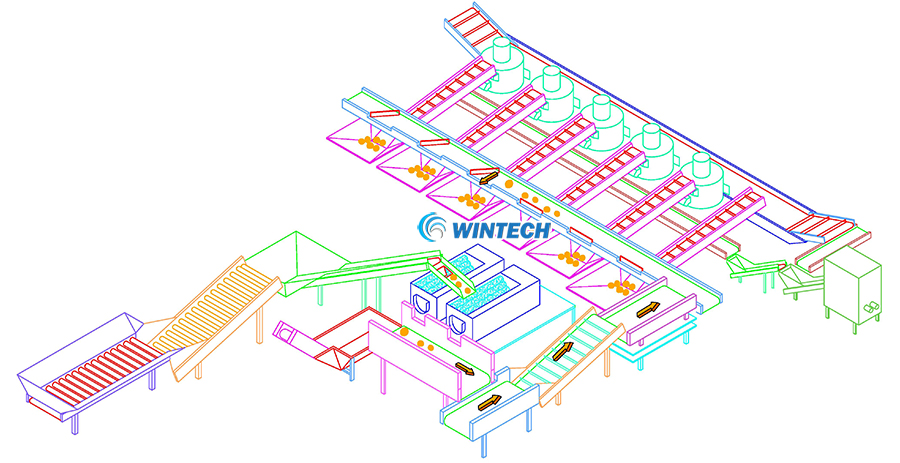

Peeled potato day / 8~10 tons production facility (automatic production line of five potato peelers)

Raw material automatic washing and automatic input facility line

Hydraulic cylinder / air cylinder mounted on U-Type bulbs and tubers washing machine: Automatic discharge equipment

Features : By mounting hydraulic cylinder / air cylinder on U-Type bulbs and tubers washing machine, it is device that automatically raises and lowers, automatically opens and closes, and automatically discharges the bulbs and tubers that has completed washing

2 automatic potato peeling facilities (Peeled potato ±3 ton production facilities)

Peeled potato production line

Peeled potato production facilities Lay Out

Korea's best peeled potato automatic production line

Tone bag input of raw material

Automatic washing discharge

Control Panel

Automatic potato insert

Pallet packing

Automatic peeling