Green Onion Peeler

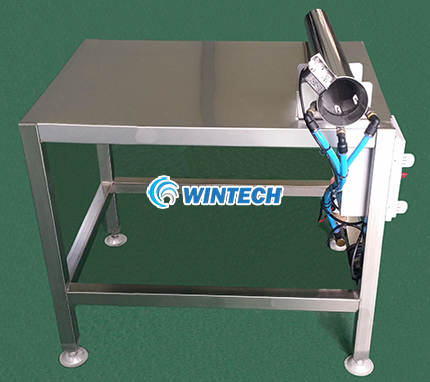

Combined Green Onion, Scallion Peeler (Pneumatic Injection)

| Model | Combined Green Onion, Scallion Peeler |

|---|---|

| Specification | 600W X 1000D X 500H |

| Peeling method | Pneumatic (air injection) (Compressor requires 10hp or more) |

| Output | 300kg~500kg Day(8h) (according to expertise…) |

| Peeling event | Spring onion , chives |

| Required person | 1 person (300 ~ 500kg production according to proficiency) |

| Peeling way | Peeling is finished simply after placing 3~5 green onions inside circular hole and shaking 2~3 times. Air injected only when insertion of green onions is detected by sensors. |

Peeling efficiency gets much higher if it is peeled after cutting the root for both spring onion and chives, and also the productivity increases.

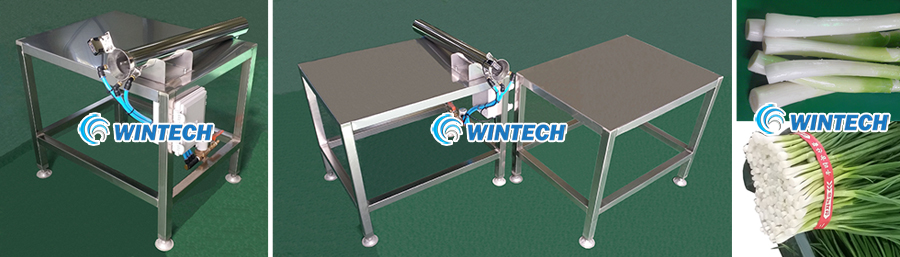

Win Tech Co., Ltd. Pneumatic spring onion / chives peeling work

Economic aspects of Win Tech Co., Ltd. spring onion / chives peeling machine

Chives 1 unit = 1,980 won

Peeled chives 1 unit = 5,800 won

Peeling/ root cutting cost = 3,820 won

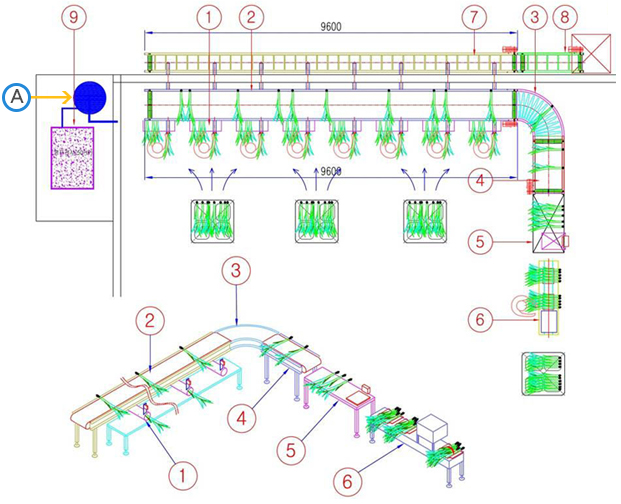

Peeled spring onion production equipment line

Peeled spring onion production equipment line, 4~5 tones daily

Peeled spring onion production of 4~5 tones daily, produces high quality and clean peeled spring onion by using the pneumatic spring onion peeler.

Spring onion peeler (Pneumatic)

Production of high quality, clean peeled spring onion

| NO | DESCRIPTION | SIZE | MATERIAL | QTY |

| 1 | Spring onion peeler | 8h/±350kg | SUS304 | 8 |

| 2 | Completed products transporting conveyor | 800 x 9600 | SUS304 | 1 |

| 3 | round conveyer | R1200 | SUS304 | 1 |

| 4 | transporting conveyor | 800 X 1500 | SUS304 | 1 |

| 5 | weighing work stand | 800 x 1500 | SUS304 | 1 |

| 6 | spring onion binding machine | 1h/450dan | SUS304 | 1 |

| 7 | by-product transporting conveyor | 600 x 9600 | SUS304 | 1 |

| 8 | by-product elevating conveyor | 600 x 2000 | SUS304 | 1 |

| 9 | screw compressor | 50HP | SUS304 | 1 |

| A | Air tank |