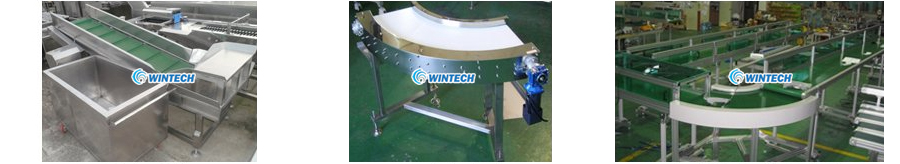

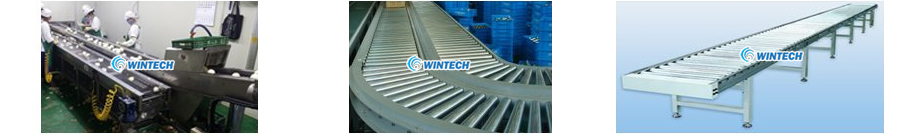

Conveyers for transferring agricultural products

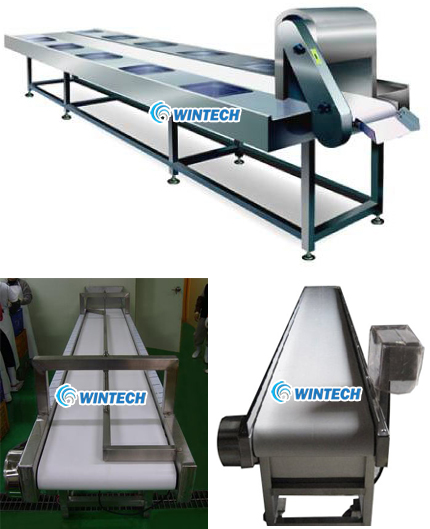

1 Stage screening conveyor

| Model | 1 Stage screening conveyor |

|---|---|

| Specifications | Order production according to the size, length, height of the user. |

Raw material cleaning work is convenient with the workstand attachment on the side of belt conveyor.

Maximize work efficiency and maximize space

Can be order produced according to the user.

It is equipment that enables transport to next process, like on one direction the products that need screening(cleaning), on one side the completed product.

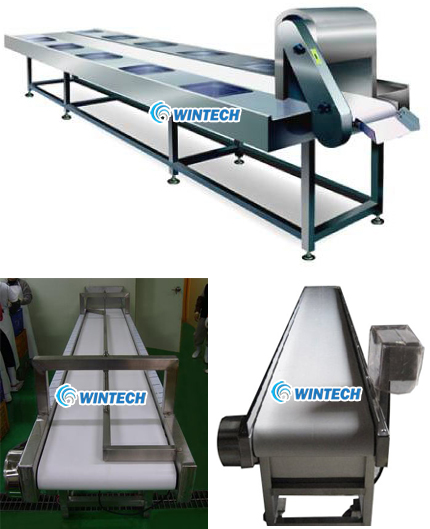

2 Stage screening conveyor

| Model | 1 stage, 2 stage belt conveyor |

|---|---|

| Specifications | Order production according to the size, length, height of the user. |

With a two-stage conveyor, it is possible to simultaneously work on the supply of raw materials, the transfer of raw materials, and the discharge of by-products.

Maximize work efficiency and maximize space

Can be order produced according to the user.

Worktable can be mounted on 2 stage conveyor.

3 Stage screening conveyor

| Model | 1st, 2nd, 3rd stage belt conveyor |

|---|---|

| Specifications | Order production according to the size, length, height of the user. |

With a three-stage conveyor, it is possible to simultaneously work on the supply of raw materials, the transfer of raw materials, and the discharge of by-products.

Maximize work efficiency and maximize space

Can be order produced according to the user.

Worktable can be attached to 2 stage intermediate conveyor.

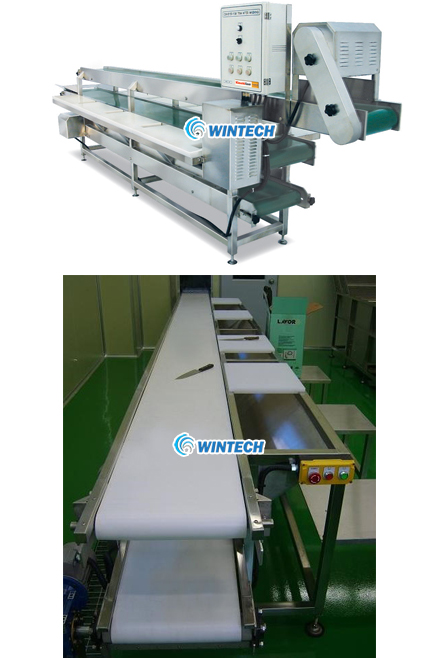

Roller conveyor

| Model | Roller conveyor |

|---|---|

| Specifications | It can be order produced according to the usage situation. |

90 degrees, 180 degrees, S type, inclination type, and others can be changed freely.

It can be connected with any kinds of products, and possible to adjust the length.

As it has stopper device, it has function of the product's dropping prevention.

With the Pin connection, the length adjustment is simple.

Product is light and the movement is simple.

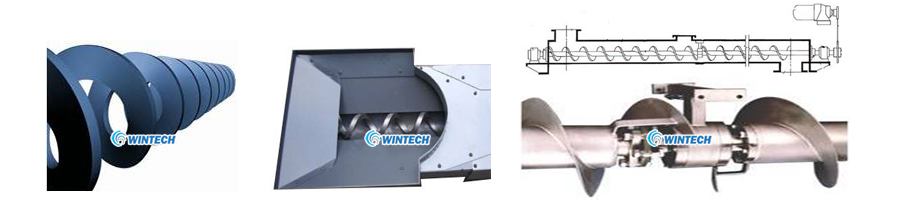

Screw conveyor

Main axis screw conveyor

A conveyor that pushes a conveyed object by rotating a spiral in a U-shaped trough or cylindrical casing

Non-axis screw conveyors

It has a structure with no central axis of rotation, which is a single beam structure that has a large transportation volume ratio and can be supported by a drive shaft bearing without a axis and it is not affected by shaft force and eccentric deformation.

| Item | Non-axis screw conveyors | Main axis screw conveyor |

|---|---|---|

| Trough shape | U-shape, round shape | U-shape, cylindrical shape |

| Transport volume rate | High transportation volume | Less transportation volume |

| Whether it has hanger or not | Not needed with no relation to the length. | Installed at intervals of 3~5m |

| Transport features | Because there are no axes and hanger, it is possible to transport all goods such as sticking or cohesive goods and solid goods | Limitations on selection of packages due to interruption of transport and as the transportation volume ratio is small. (Mainly used for powder transfer) |

| Maintenance management | Easy to handle and maintain | Frequent inspection and repair is required for the shaft force, deformation and bearing due to transfer load. |

| Screw thickness | 15~30mm | Maximum 8mm |

| Usage length | Maximum 25 ~ 30m | 10~12m |

Screw style : Adapt screw style of shape that is adequate to the site

Other Conveyor

- Inserting Belt Conveyor

- 90 Degree Turnbelt Conveyor

- Belt Conveyor Automatic Line Transfer System

- screening conveyor

(Removal of root and stalk of an onion) - Roller conveyor line system

- Roller conveyor

- Asynchronous conveyor, order type

- Free Roller Conveyor

- Up and down belt conveyor